Supersonic wind tunnel

A supersonic wind tunnel is a wind tunnel that produces supersonic speeds (1.2<M<5) The Mach number and flow are determined by the nozzle geometry. The Reynolds number is varied changing the density level (pressure in the settling chamber). Therefore a high pressure ratio is required (for a supersonic regime at M=4, this ratio is of the order of 10). Apart from that, condensation or liquefaction can occur. This means that a supersonic wind tunnel needs a drying or a pre-heating facility. A supersonic wind tunnel has a large power demand leading to only intermittent operation.

Contents |

Restrictions for supersonic tunnel operation

Minimum required pressure ratio

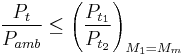

Optimistic estimate: Pressure ratio  the total pressure ratio over normal shock at M in test section:

the total pressure ratio over normal shock at M in test section:

Examples:

Temperature effects: condensation

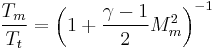

Temperature in the test section:

with  = 330K:

= 330K:  = 70K at

= 70K at  = 4

= 4

The velocity range is limited by reservoir temperature

Power requirements

The power required to run a supersonic windtunnel is enormous, of the order of 50 MW per square meter of test section. For this reason most wind tunnels operate intermittently using energy stored in high-pressure tanks. These windtunnels are also called intermittent supersonic blowdown wind tunnels (of which a schematic preview is given below). Another way of achieving the huge power output is with the use of a vacuum storage tank. These tunnels are called indraft supersonic wind tunnels. Other problems operating a supersonic wind tunnel include:

- adequate supply of dry air

- wall interference effects

- high-quality instruments capable of rapid measurements due to short run times on intermittent tunnels

Tunnels such as a Ludwieg tube have short test times (usually less than one second), relatively high Reynolds number, and low power requirements.

Further reading

- Pope, A.; Goin, K. (1978). High-speed Wind Tunnel Testing. Krieger. ISBN 088275727X.

See also

- Wind tunnel

- Low speed wind tunnel

- High speed wind tunnel

- Hypersonic wind tunnel

- Ludwieg tube

- Shock tube